2024 - Solar Sinter

Category

Daylight In Buildings - Region 1: Western Europe

Students

Anders Eugen Lund

Teacher

Runa Johannesen

School

Royal Danish Academy

Country

Denmark

Download

Download project board ↓

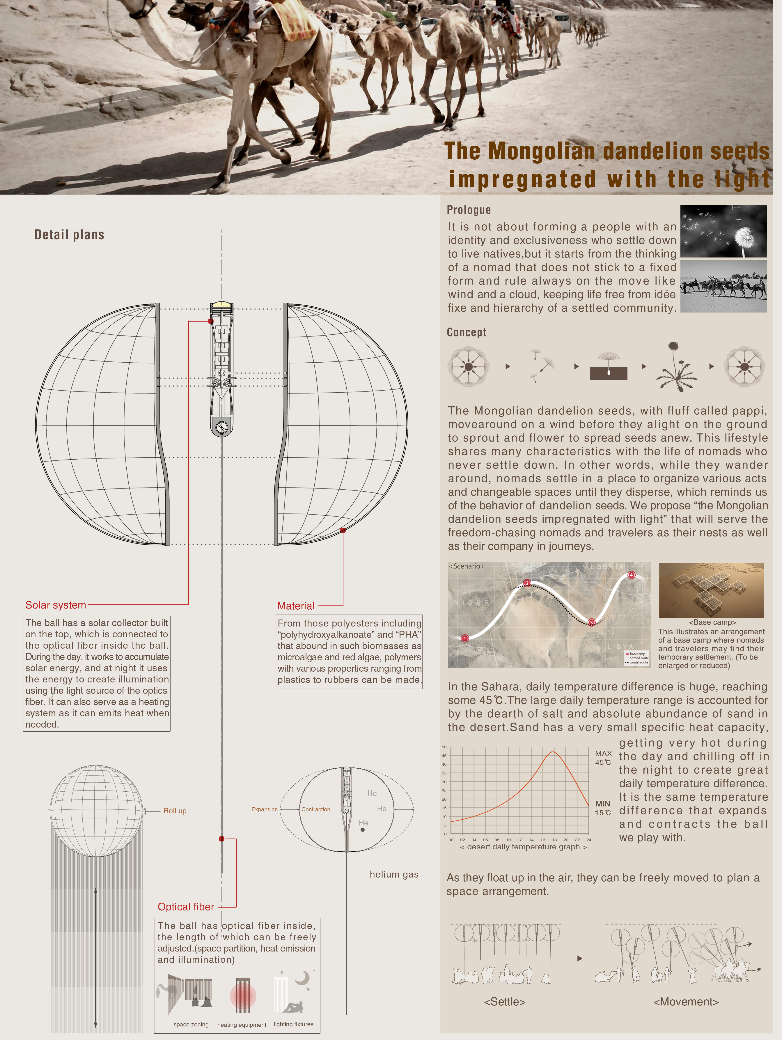

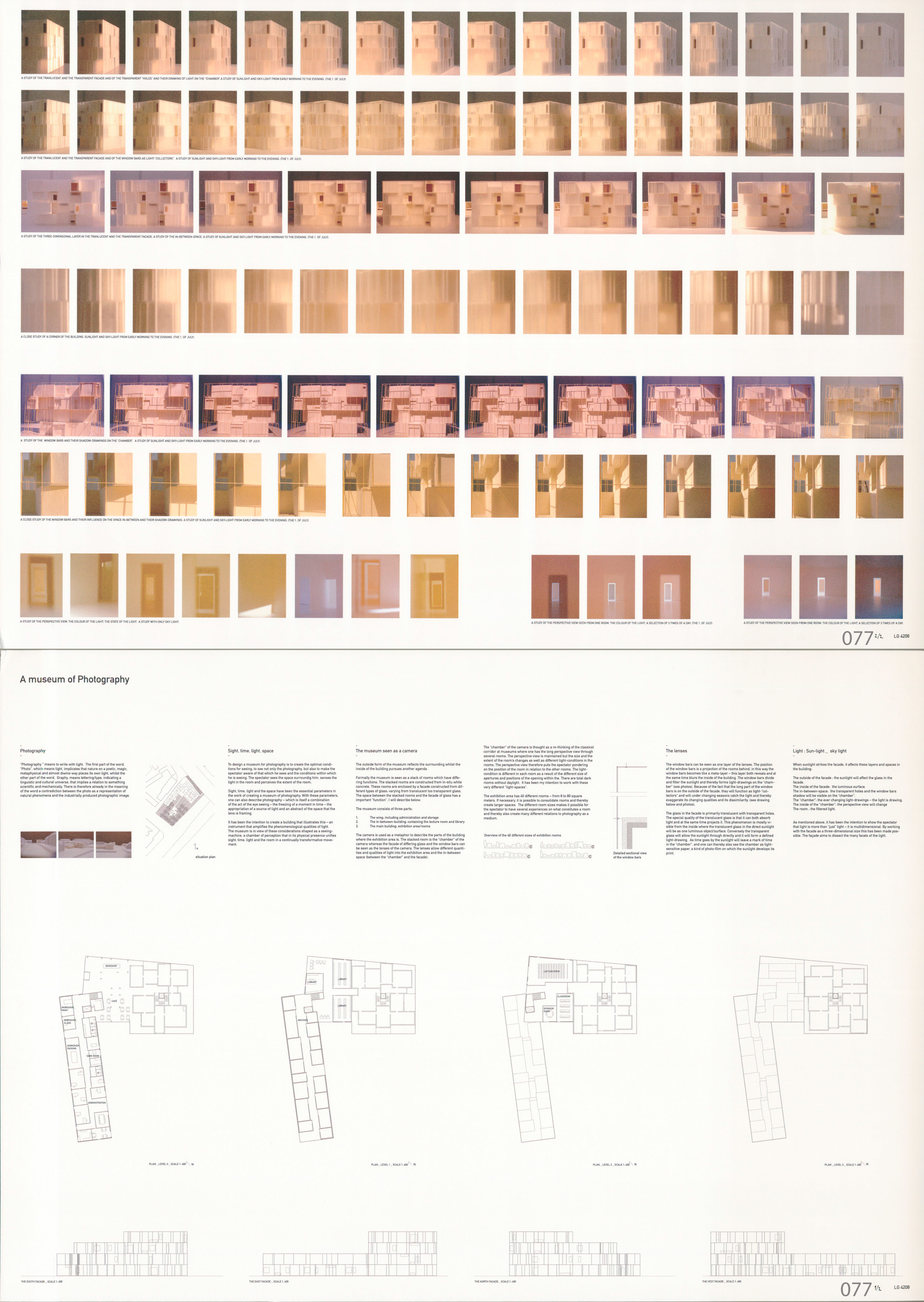

Lens sintering clay plaster facades of Rajasthans vernacular housing using solar rays, to better their resistance to the monsoon rain. A large part of Rajasthans rural population lives in clay plastered adobe houses. The thermic properties of these homes make them ideal for the hot conditions experienced during summer, while keeping its inhabitants warm during the cold winter nights. However these walls are washed off during the heavy monsoon rains, requiring frequent repairs and maintenance. Outside the monsoon the sky is always clear, and the sun is out.

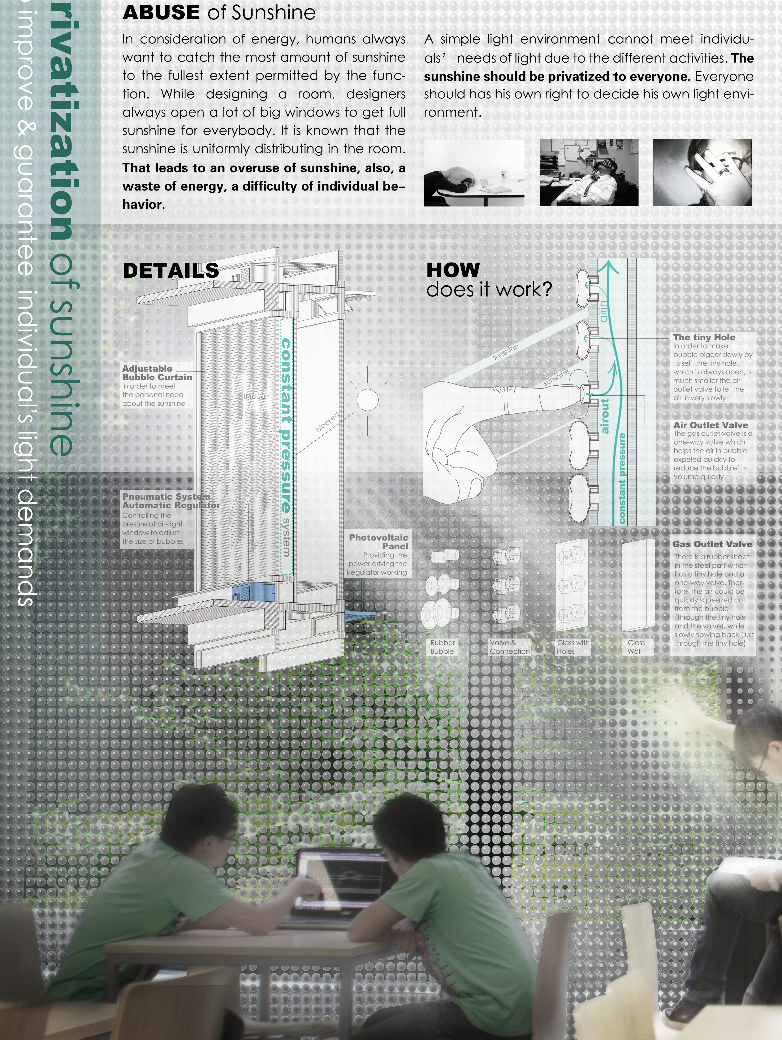

This project seeks to investigate the possibility of enforcing already built plaster facades, in rural Rajasthan in India, by using a Fresnel lens to solar sinter the plaster, making it ceramic and thus, more resilient. A fresnel lens was mounted on a frame designed to scan the surface of the facades. The lens was adjustable in all dimensions to optimize the sun angle. Local soil was collected and mixed into plaster. Combining the local tradition of decorating ones plaster facade, with the properties of sintering clay turning it ceramic, a strengthening pattern was scanned onto plastered boards. This was done in an attempt to keep the traditional vernacular architecture alive, lightening the inhabitants workload and ensuring continued comfort throughout the seasons.

A large part of the prototype came from the recycling and reuse of aluminium scraps and disgarded parts from previous prototypes. The studio has a storage for excess material. Through adjustments of the design throughout the building process the prototypes design was adapted to this surplus of metal parts.

This was done for the following reasons:

To minimize the need to purchase new aluminium.

As a very emission heavy material, any reduction in production is a plus.

To minimize cost.

To prove scalability.

The prototype being made out of spare metal parts and scraps is a step in the direction of a decentralized and cost effective production of lens frames. This approach rendered a fully functioning prototype, and settles within a culture very much alive in many places across the world, of making what you need from the resources available. A tradition where design is driven by necessity, and the notion of urgency outweighs the need for holistic design. This

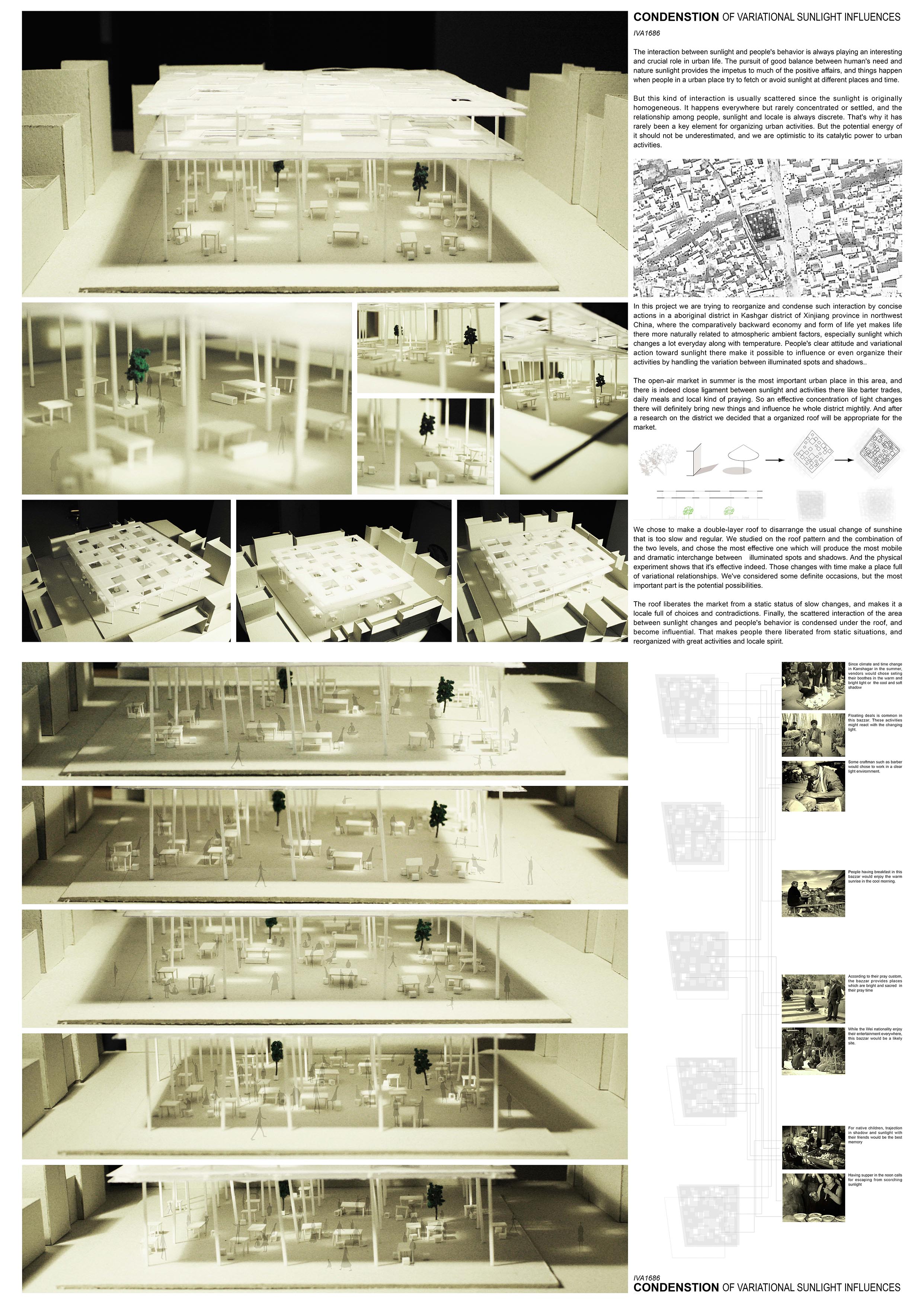

approach was theorized by people like Ernesto Oroza, who calls it Apaño coming from a Cuban context, and in India, the approach is often described by the word Jugaad. The test proved the lens’ abilities to alter both the physical and esthetic properties of clay plaster. With sintered plaster showing slight improvement when in contact with water compared to

non-sintered plaster. A bigger lens would be able to burn the plaster at a higher temperature at the focal point, thus improving the strengths of the sintered patter, probably further improving its properties agains water. A higher focal point temperature would also potentially reduce the time consumption of the sintering process. This would release more time to develop the esthetic implications of the sintered patterns, and their relations with the traditional decor in clay plaster building in Rajasthan.