2024 - Gill Gardens

Category

Daylight in buildings - Region 3: The Americas

Students

Audrey Chen

Simone Darveau

Kailing Mai

Teacher

David Correa

School

University of Waterloo

Country

Canada

Download

Download project board

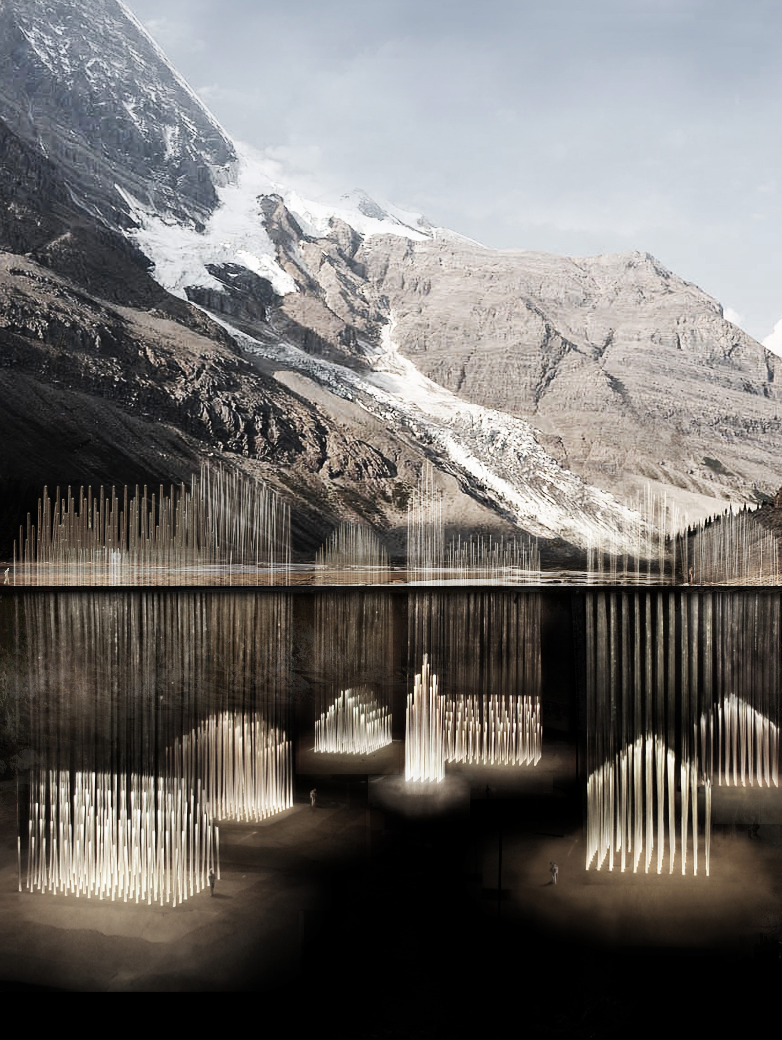

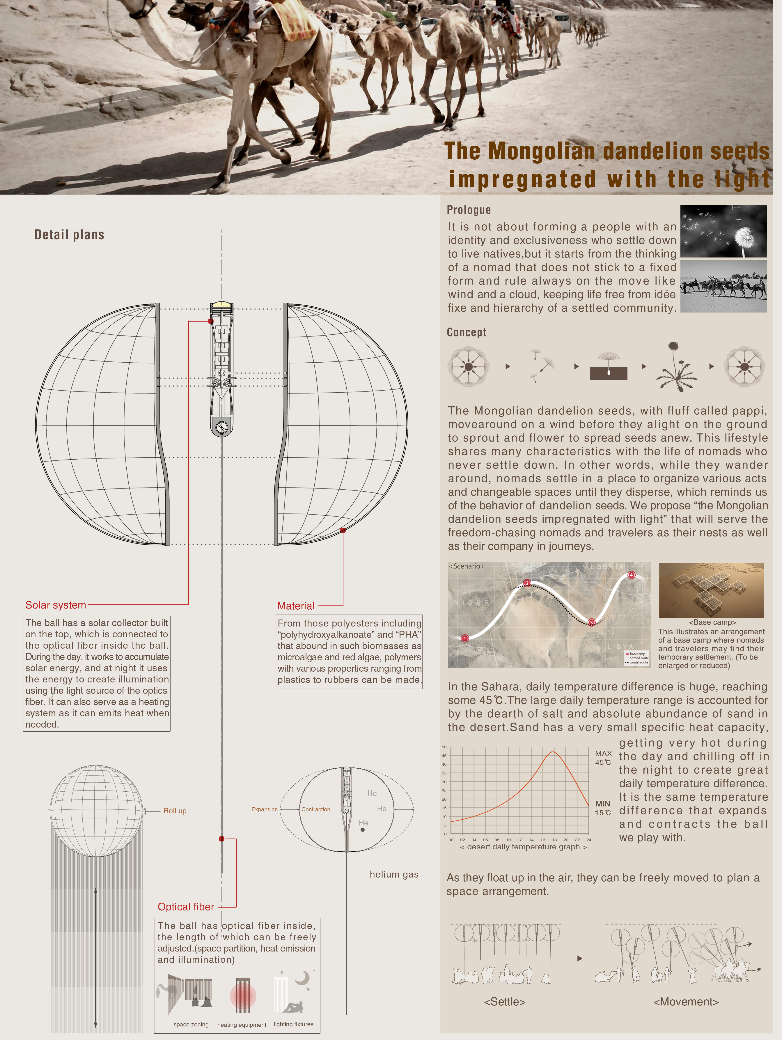

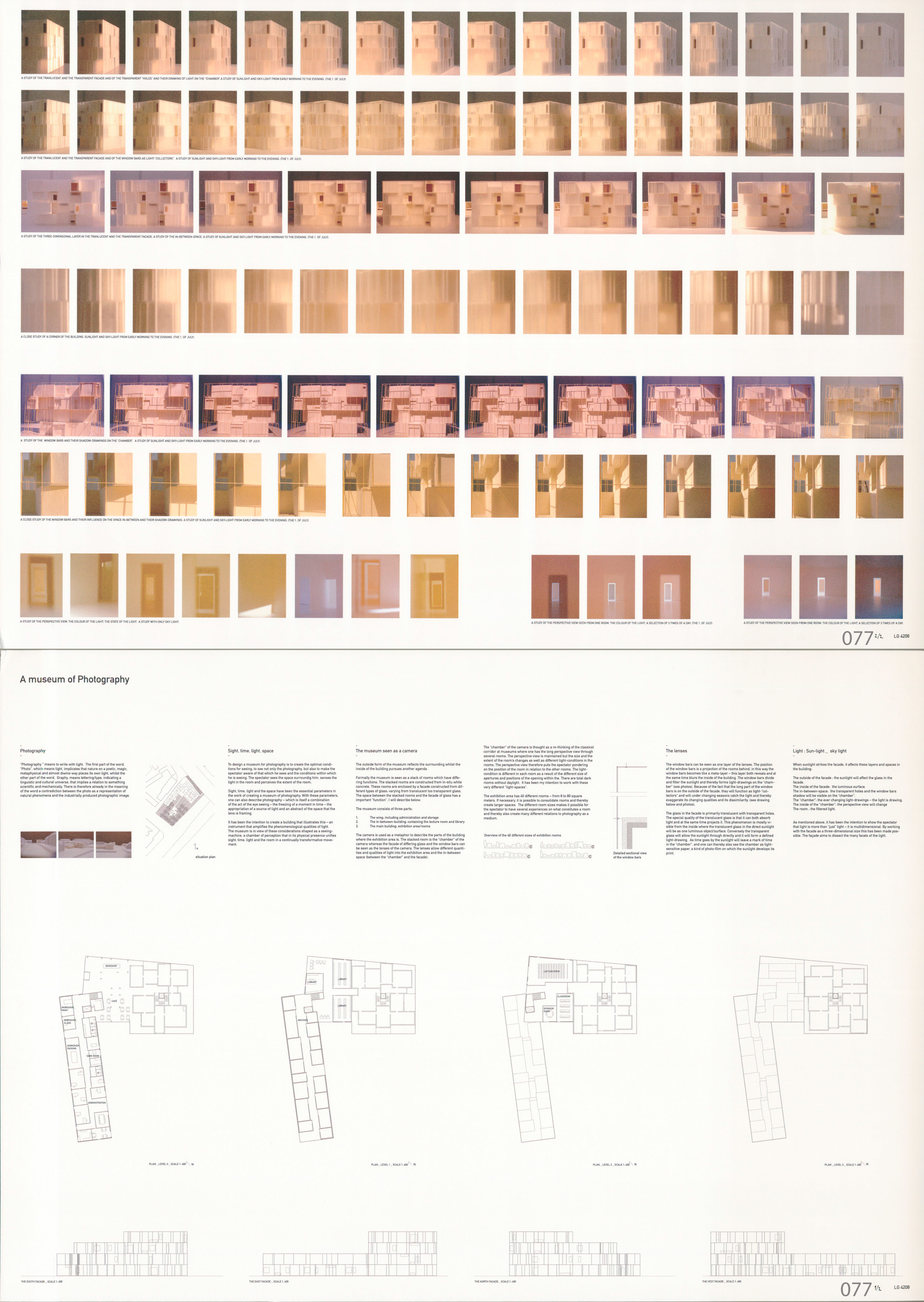

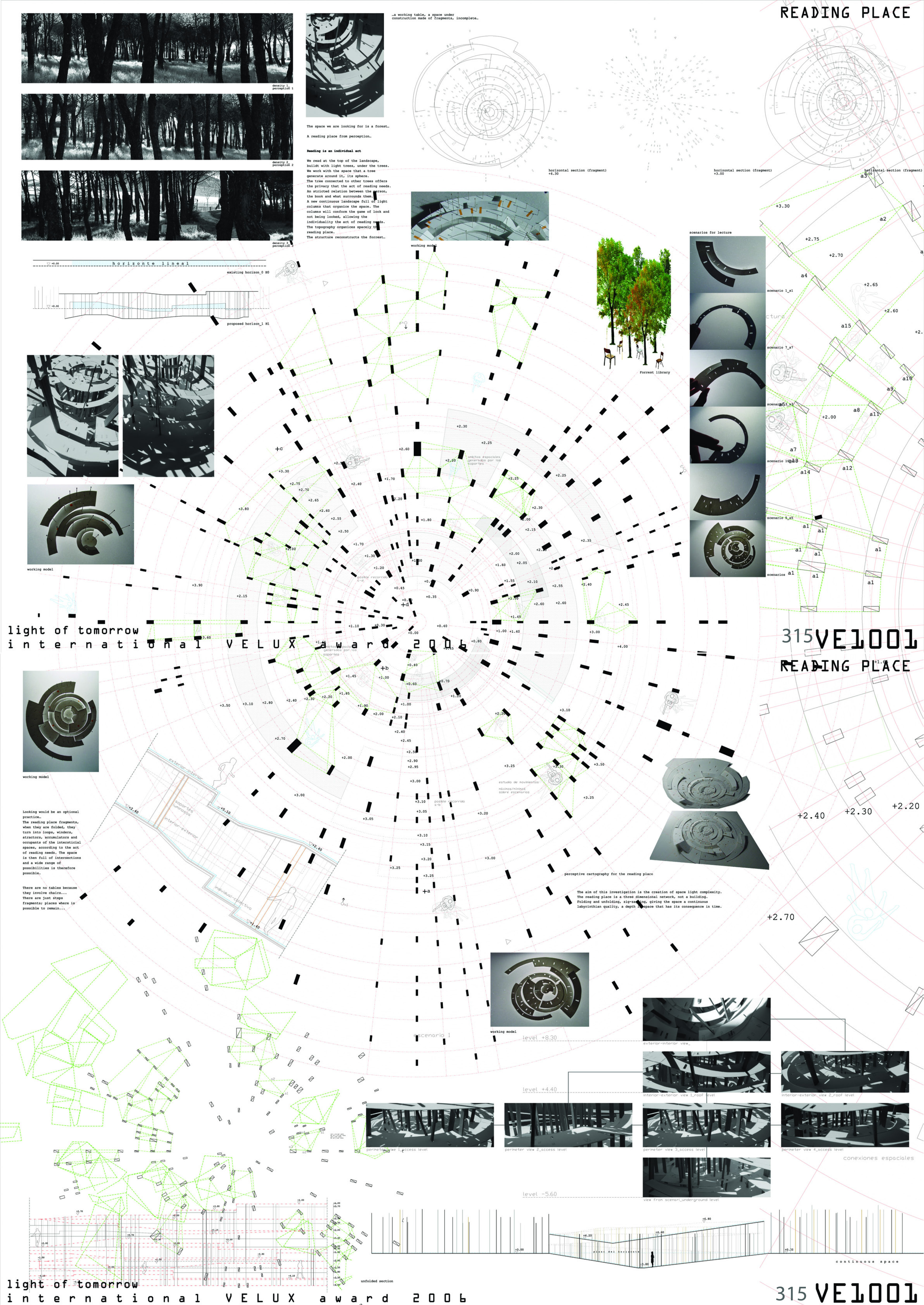

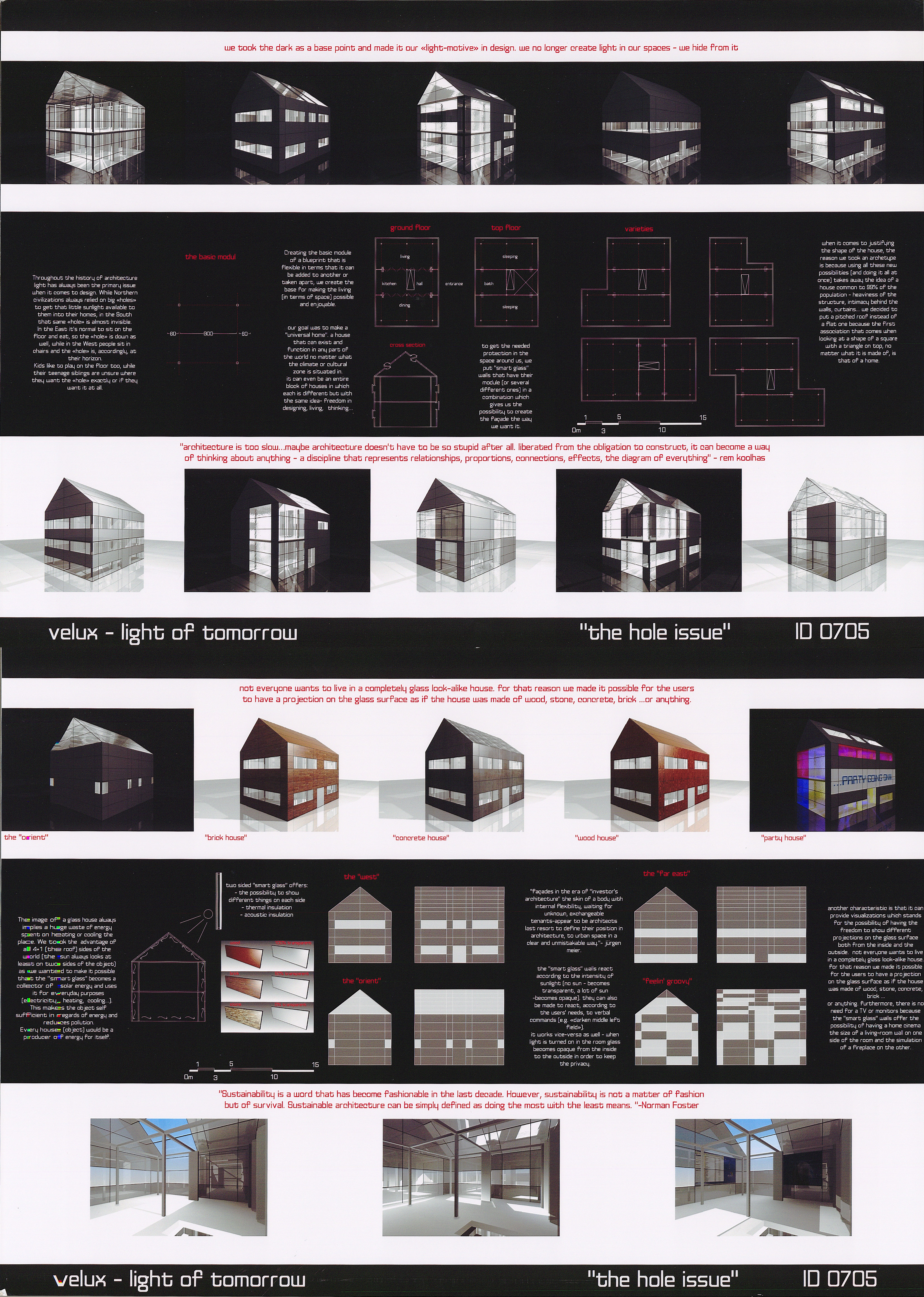

Gill Gardens aims to be a collaborative, hands-on botanical garden centered around learning and engaging with nature. This project explores an innovative architectural solution by upscaling adaptive wood bilayer systems, inspired by the hygroscopic actuation of the lamellae (gills) of the Button Mushroom (Agaricus bisporus), to create a climate-responsive louvre system that leverages the inherent properties of wood for controlled shape-changing transformations based on fluctuations in relative humidity at a daily and seasonal scale, offering a biomimetic and material-centric alternative to conventional mechanical kinetic facades.

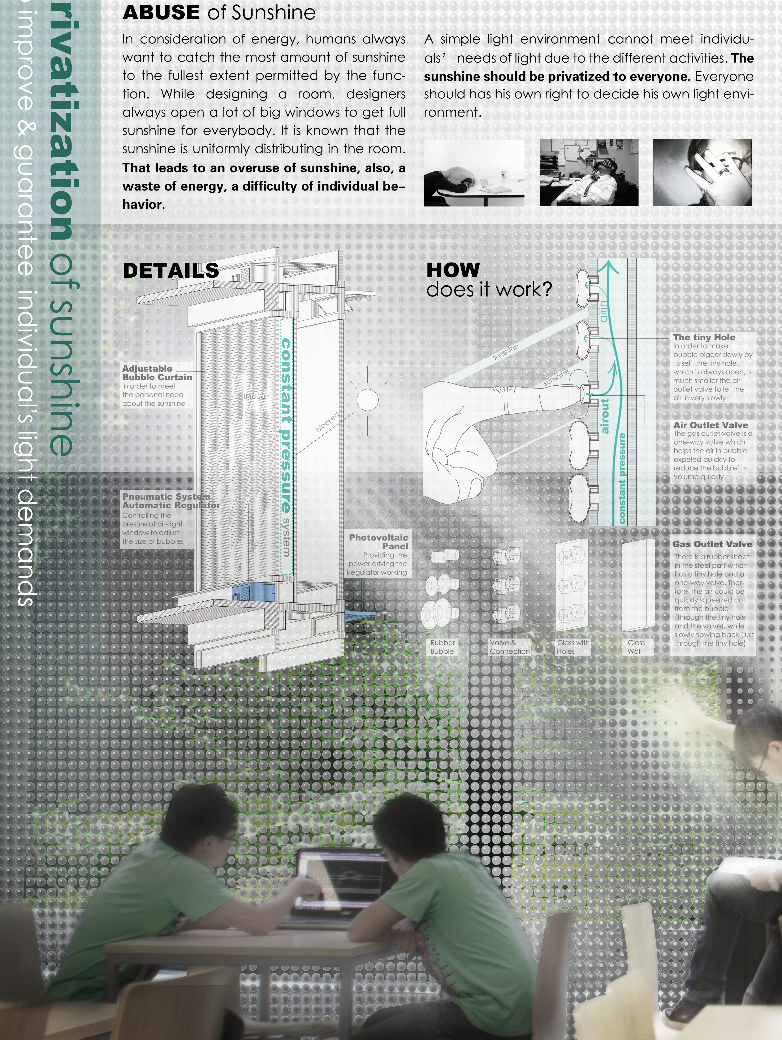

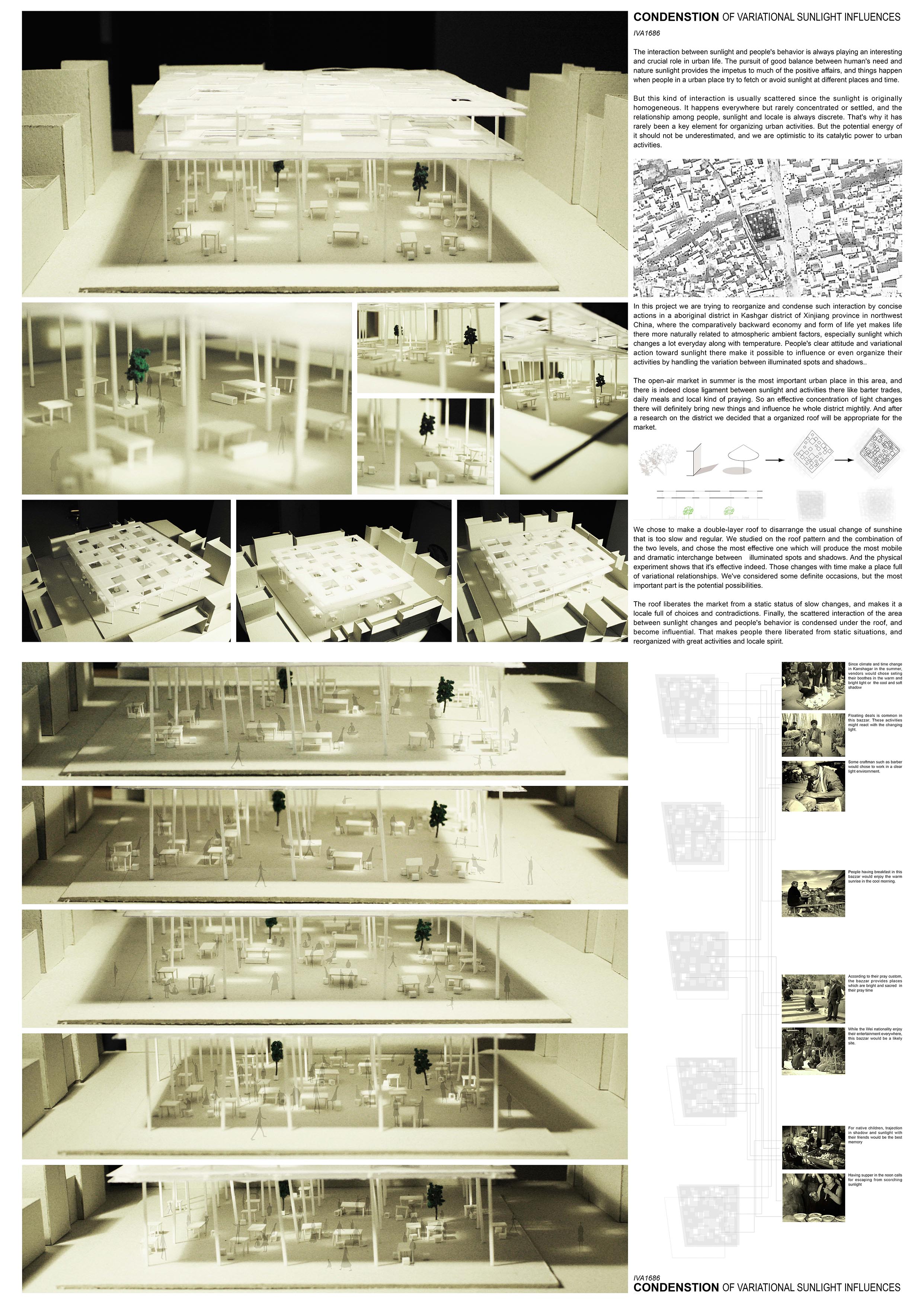

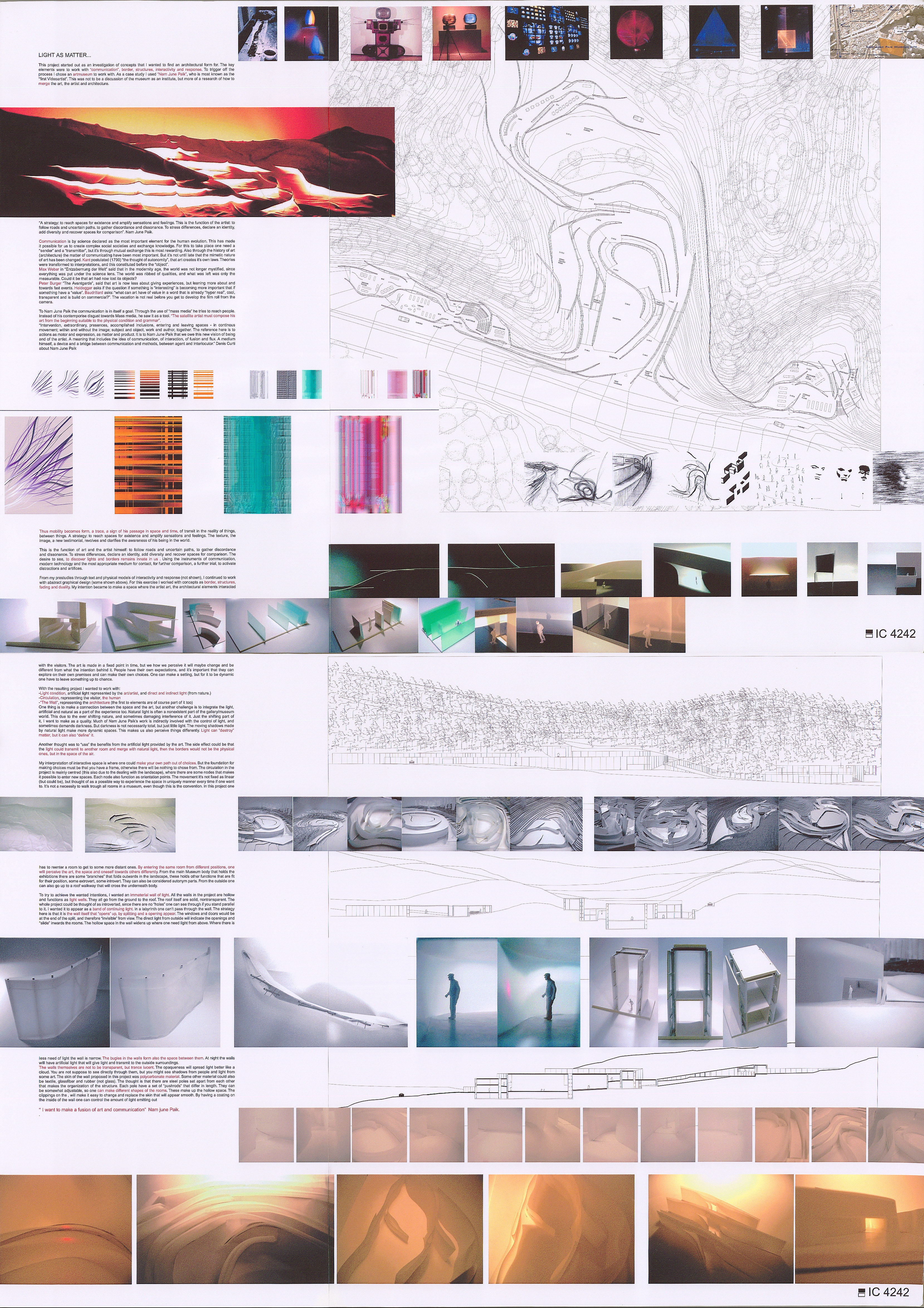

An active shading system is essential to recognize the diverse sunlight demands of various organisms and plants within the biomes of the botanical garden. The foremost design strategy revolves around passive solar design and a climate-responsive louvre system to optimize daylight and control solar heat year-round. The louvres open and close in response to changes in exterior relative humidity. For example, to maintain a temperate interior climate during colder seasons, relative humidity is high thus the louvres would open to maximize winter sunlight. Conversely, during the summer months, relative humidity is low causing the curling of louvres to mitigate solar heat gain and maintain thermal comfort.

The louvres also contribute to visual delight through playful shadow patterns, providing compelling views through the louvres, and effective daylighting that can be tailored to a variety of specific settings and façade systems. The dynamics and temporal quality of daylight enhance health and well-being, fostering a deeper connection between occupants and their surroundings

The louvres operate through the natural expansion and contraction properties of American White Beech combined with a passive plywood layer, forming a hygroscopic bilayer system. CNC kerfing is used to create milled grooves in the louvres to control the material flexibility and moisture dissipation across the bilayer structure. The deeper the kerfing, the greater flexibility and speed the plywood experiences. The shallower kerfing would result in more resistance to the active expansion, allowing more customization in the louvres. For further customization, parameters such as louvre depth, placement density, and speed of the closure/curling can be tailored toward specific needs that can impact the interior conditions throughout the day and seasons.